Basins Program

2021/06/30

Basins Program

SONIA BATH CATALOG

We work to provide you with a wide range of possibilities for your bathroom.

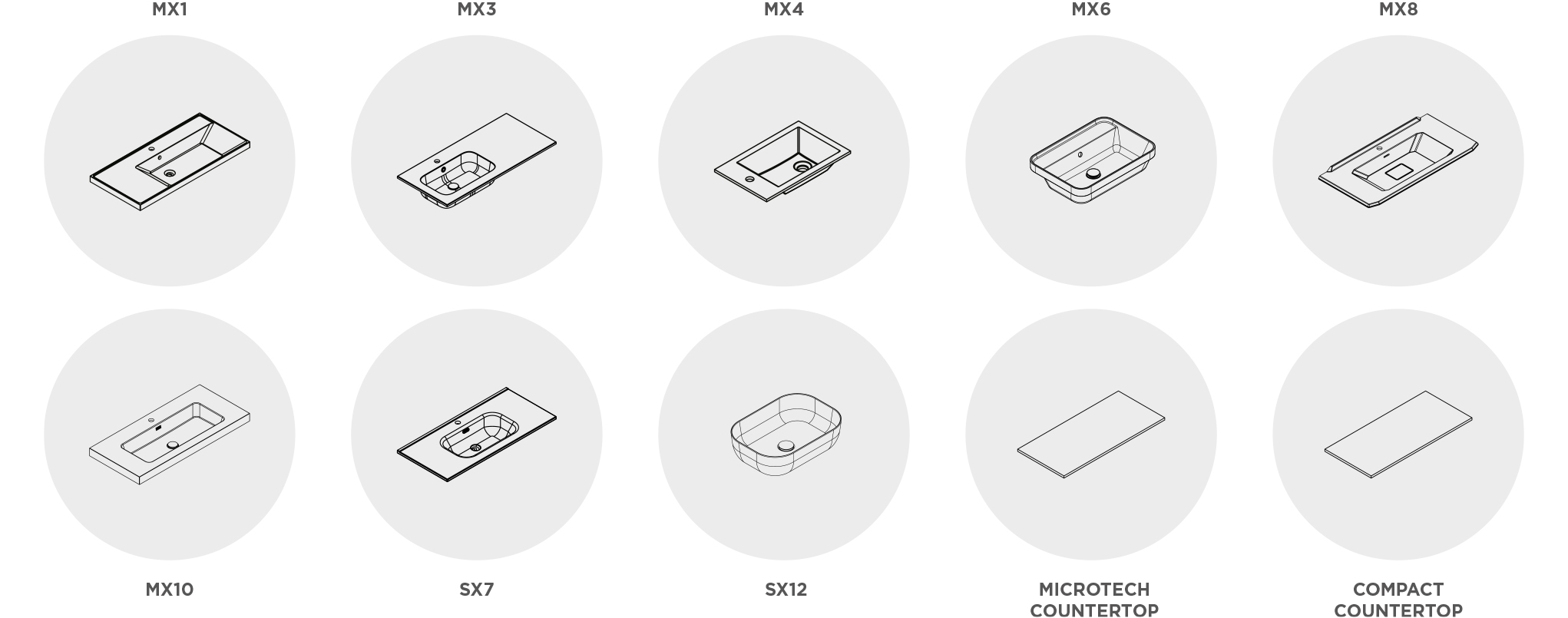

BASINS AND COUNTER TOPS

7 + 2 COLLECTIONS

All the sinks and countertops you need to completeyour furniture and make your bathroom a unique space.

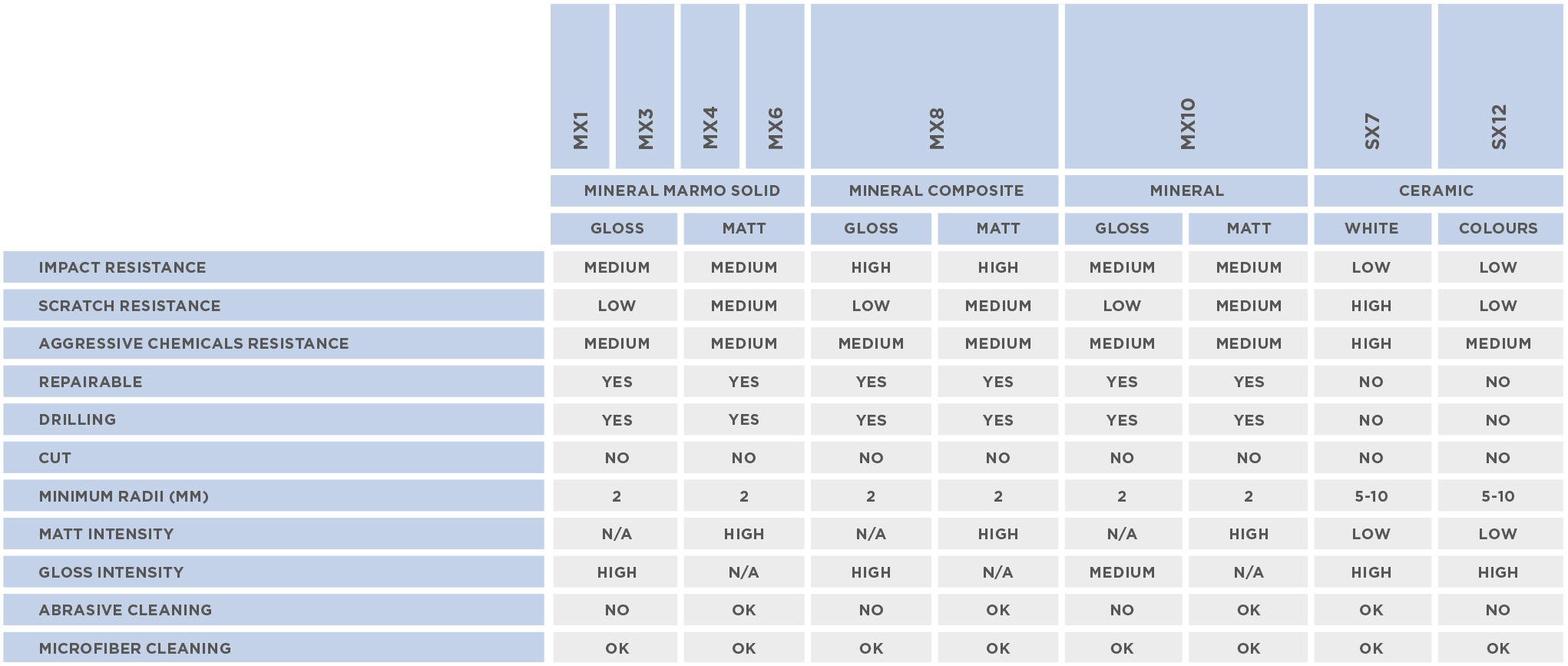

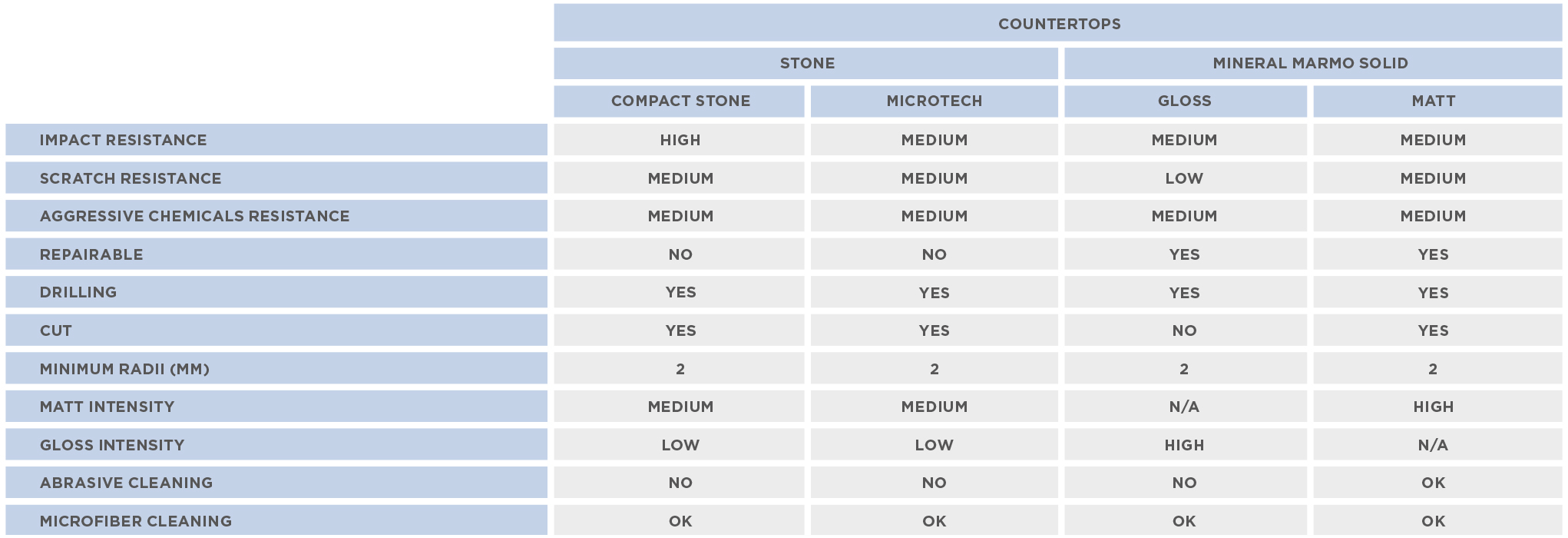

CHARACTERISTICS

Comparative table of characteristics and particularities of the basins and countertops according to the collection.

MINERAL MARMO SOLID

It is a ductile material, of new generation, that is modeled by injection and

allows the development of complex application volumes and surfaces

in many areas of the market: washbasins, bathtubs, floors, furniture, etc.

It is composed of 75% natural mineral products

(calcium carbonate and aluminum trihydrates) and 25% polyester resin.

The surface hardness of this material lies in the polyester film

covering the surface so that the mechanical and chemical characteristics

make it suitable for bathroom decoration and public environments.

Available in two surface finishes:

Gloss - Mineral Marmo.

Matt - Mineral Solid.

MX1 - MX3 - MX4

MINERAL COMPOSITE

It is a variant of Mineral Solid/Marmo with improved resistance characteristics.

Composition 75% rock ore ground with dolomite and 25% resin

Polyester elastic is coated with a layer called Nancoat.

Thanks to this, the product is very resistant to mechanical impact and temperature exposure

extreme as well as having anti-bacterial properties due to its low water absorption.

Coatings of this type are also used to coat surfaces

of ship hulls, windmill shovels, etc. that is,

sites exposed to continuous contact with adverse elements.

Available in two surface finishes:

Gloss - Mineral Composite Gloss.

Matt - Mineral Composite Matt.

MINERAL

It is another variant of Mineral Marmo/Solid in the same proportion of materials

75% mineral components and 25% polyester resin.

It maintains the same strength and durability performance as the previous one to a standard quality level.

Available in two surface finishes:

Gloss - Mineral Gloss.

Mate - Mineral Matt.

CERAMIC

It is one of the most traditional materials in the manufacture of medical devices.

Even with limited forms, ceramic is the most durable material on the market today.

With a complex and artisanal manufacturing system, the ceramic paste

is a natural material composed basically of clay and kaolin. During the manufacturing process

Finely ground quartz and feldspar are added to both materials in very precise proportions.

The surface finish of this material is achieved by applying a mineral white enamel

in the raw parts, and after a cooking phase of approx. 1280º, reaches its hardness and shine

characteristic so-called vitrified. The different colours in which this material is presented have a

different process the vitrified. In this case we are talking about a high resistance kiln dried paint.

A quality ceramic piece is distinguished by the uniformity in the surfaces,

absence of pores, surface pinches and a uniform white finish throughout the piece.

MICROTECH

It is a derivative of Natural Compact Stone with the same manufacturing process.

The difference is that the ground stone used is a common rock that once licked

different coatings of colour tones are applied.